This is my last post for 2014 I hope you have gotten some enjoyment from my ramblings...

This month I got the news my wife in 2015 has a job back in Adelaide and it is a little under one hour drive from home. So after her working in the country for over a decade she will be living at home full time! It will be great to be living together in the same house again. Not sure how that will impact my hobby activities. tho....

Well despite a trip to Pt Augusta for my wife's work Xmas show and bringing the first carload of her stuff home I did get some modelling time. Firstly Wayne and I decided on a naming convention for the signal system components and I started learning the best way to terminate ribbon cable to 10 pin female headers. I can also report that the second version of the Ambient Light Detector PCB has arrived, more work on the design of the Standard Signaling Module has been achieved leading to s breadboard prototype, a testing module and an order for some prototypes.

This is the generic Red-Yellow-Green controller - I am using Rob Paisleys 3 light signal driver and Wayne intends to use the one in the March 2001 Model Railroader Magazine.

Previously known as the Ambient Light Detector PCB - the new name better depicts what it actually does.

Previously known as the Standard Signalling Module

It is hoped that there will be less confusion in technical discussions from now on.

Given the outcome my initial idea of sleving every second wire with heat shrink tubing will probably not be required.

Building the second prototype

The first board took around 4 hours to build and the second took around 3 hours.

That's it for this month.

Till the end of January or February 2015 - It depends on how moving my wife back home goes....

This month I got the news my wife in 2015 has a job back in Adelaide and it is a little under one hour drive from home. So after her working in the country for over a decade she will be living at home full time! It will be great to be living together in the same house again. Not sure how that will impact my hobby activities. tho....

Well despite a trip to Pt Augusta for my wife's work Xmas show and bringing the first carload of her stuff home I did get some modelling time. Firstly Wayne and I decided on a naming convention for the signal system components and I started learning the best way to terminate ribbon cable to 10 pin female headers. I can also report that the second version of the Ambient Light Detector PCB has arrived, more work on the design of the Standard Signaling Module has been achieved leading to s breadboard prototype, a testing module and an order for some prototypes.

Naming Convention - Signal System Components

It had become very evident that to ensure Wayne & I were always on task talking about the same bit of kit we needed to standardise! So following some rational discussion we settled on the following:Signal Light Module (SLM)

Dual Block Direction Sensor (DBDS)

Standard Signal Control Module (SSCM)

|

| Breadboard Prototype |

Dual Block Direction Sensor (DBDS)

Last month I reported that Wayne has tweaked the design and a second pilot board has been ordered to ensure we have nailed it prior to ordering the production run. Well they have arrived. |

| The second Prototype |

Building the second prototype

|

| The second Prototype under construction |

|

| The second Prototype with components mounted |

|

| Both Prototypes built and tested |

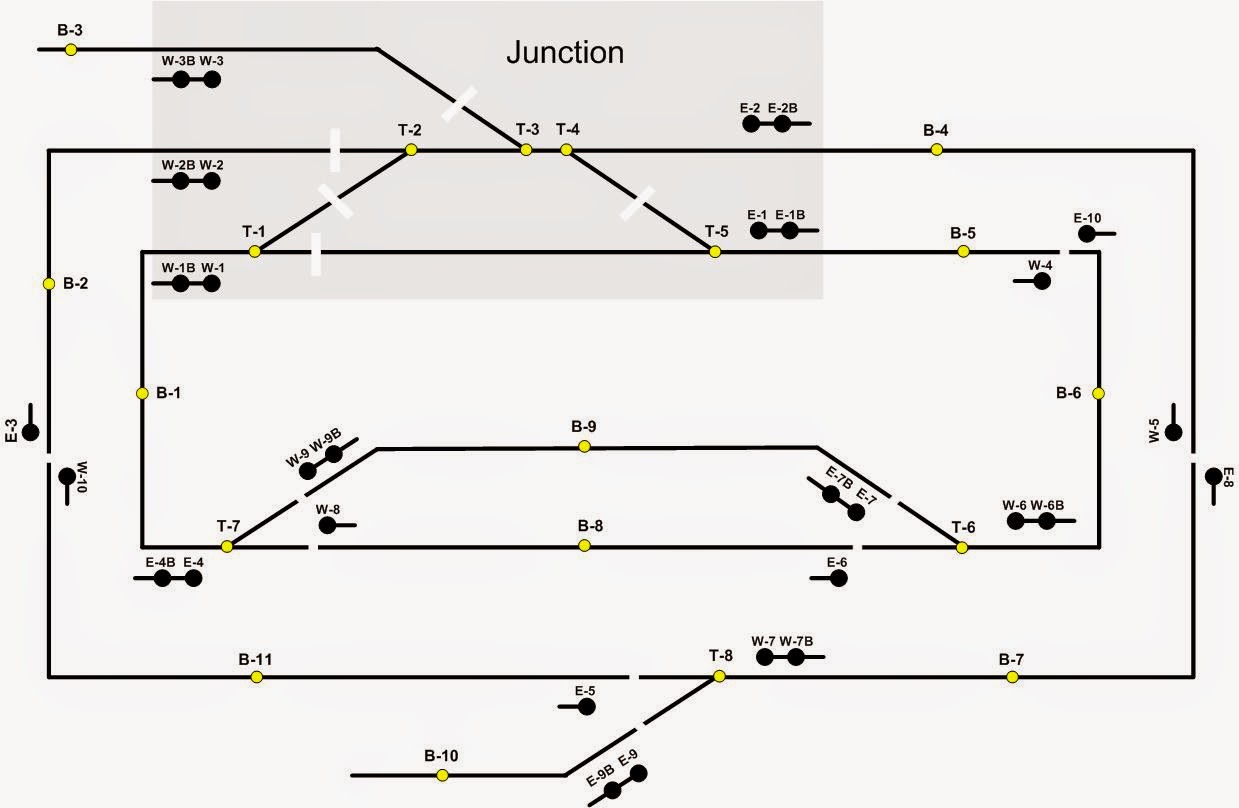

Standard Signal Control Module

The control logic was revisited and the desired outputs were mapped. Then superimposed was the outputs controlled by the Signal Light Modules (Green/Red highlight) leaving the Yellow/Blue "R's" that require control through this module. The Local Signal Heads (Ex(B) & Wx(B)), East Ahead (E+) and West Ahead (W+). The corresponding inputs for the Turnout conditions Normal or Reverse (TxN & TxR), Block Occupied Bx, Train Going East (BxE) and Train going West (BxW). The relationships can be seen in the spreadsheet below.

Last months breadboard concept design was ditched and another version devised following a rethink...

The circuit concept is:

I took the design and laid it out on bread board:

I have written the code for the controller which operated successfully.

We have refined the design some more and Wayne has designed the PCB. We are about to sent it off for production of some prototypes.

I guess when the prototypes arrive and are built we can put the total system together and do final testing before placing the "production" PCB order.

Last months breadboard concept design was ditched and another version devised following a rethink...

The circuit concept is:

I took the design and laid it out on bread board:

I have written the code for the controller which operated successfully.

We have refined the design some more and Wayne has designed the PCB. We are about to sent it off for production of some prototypes.

I guess when the prototypes arrive and are built we can put the total system together and do final testing before placing the "production" PCB order.

Standard Signal Control Module Testing

There will be a need to make quite a number of these modules so I decided to make up a test cntre which represents all the 14 inputs and and the 10 outputs. .

So here is a video that shows how it works - not perfect but you will get the idea....

Merry Christmas and A Happy New Year to all that watch my hobby exploits.

Merry Christmas and A Happy New Year to all that watch my hobby exploits.

That's it for this month.

Till the end of January or February 2015 - It depends on how moving my wife back home goes....

-ooOOOoo-

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)